Medicine

Medicine

Physics, Earth & Space

Physics, Earth & Space

I Just Want to Say One Word to You: Graphene

In the 1967 movie The Graduate, Dustin Hoffman plays a recent college grad trying to figure out what to do with his life. His graduation party includes a Bradley famous scene where a family friend takes him aside and offers sage advice: “I just want to say one word to you. Just one word.” The word? “Plastics,” with the older man further advising that “there’s a great future in plastics.” If COSM 2023 is right, then if The Graduate were remade today, that one word might very well be “graphene.”

Previous COSM conferences have covered graphene (see here and here), and COSM 2023 hosted a panel on “The Graphene Revolution,” with energy entrepreneur Ariel Malik, Bradley Larschan, CEO of Avadain, and Kevin Wyss, who recently earned a PhD in chemistry at Rice University studying under Professor James Tour.

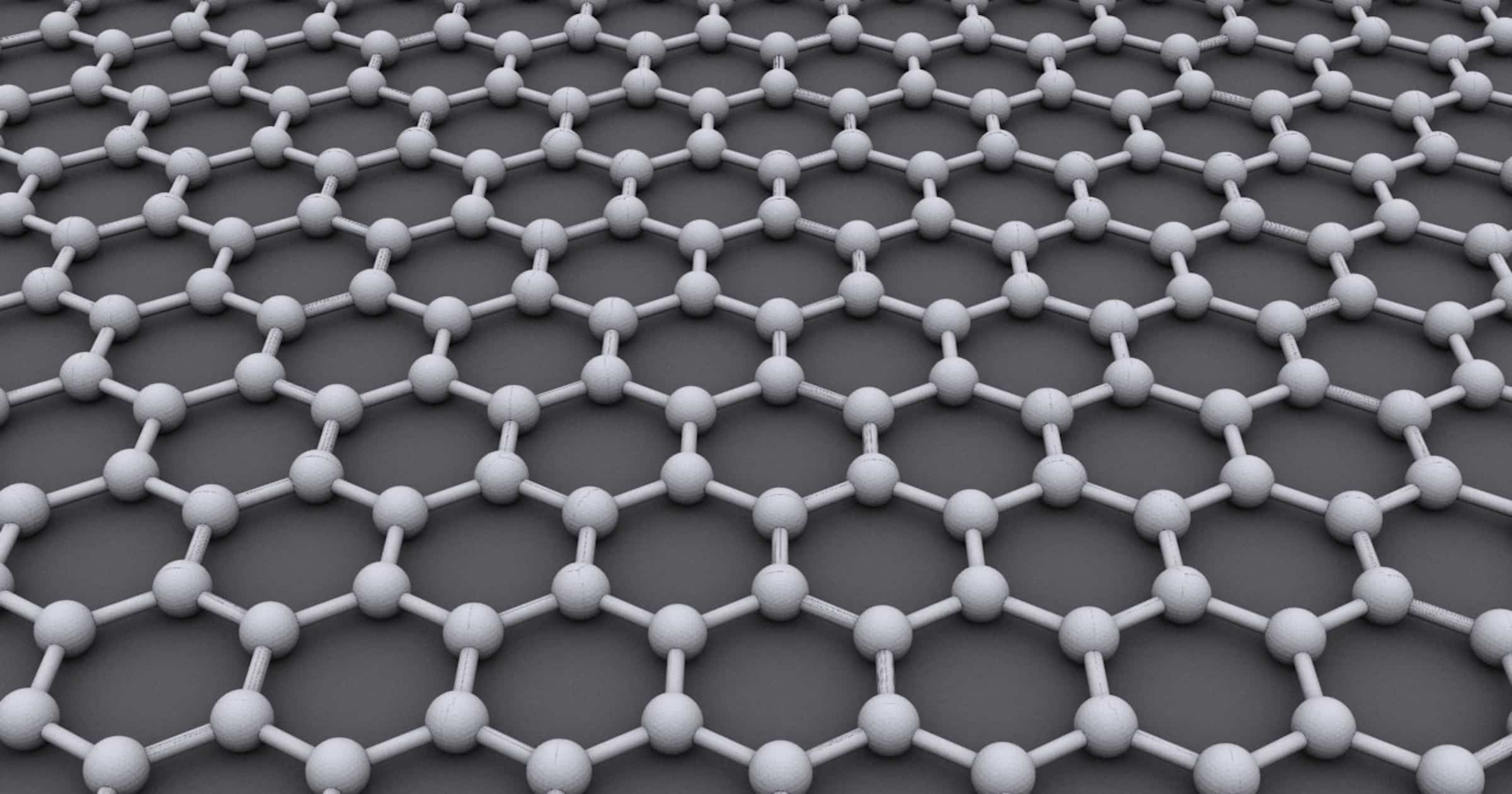

Wyss opened the panel by explaining that graphene is carbon bonded into a single, thin sheet in a honeycomb-like pattern — that is extremely strong, stable, and conductive. These special properties afford applications like strengthening cement or plastics, making flexible electronics, and stabilizing next generation batteries.

Yet Another Use for Scotch Tape

Graphene was first characterized in 2004 when two researchers took graphite — essentially layered sheets of graphene — and exfoliated individual sheets of graphene using scotch tape. In the multilayer form of graphite, carbon loses its special conductive properties and strength, becoming brittle. But Wyss explained that “if you take one layer of the graphite and turn it into graphene then you get something very strong and special.” This seemingly simplistic “top down” method of making graphene earned two scientists the Nobel Prize in Physics in 2010.

Another method, called “bottom up,” seeks to construct graphene from some carbon-based source material.

As is often the case, the different methods have tradeoffs. The top-down method yields large sheets of graphene cheaply but it’s hard to get large sheets of graphene that are defect-free. So it’s cheap but of poor quality. The bottom-up method gives higher quality graphene but the sheets are smaller and it’s more expensive; it’s high quality but expensive.

Graphene’s “Aluminum Moment”

Is there a way to create high quality graphene at a low cost? Wyss explained that graphene has recently experienced an “aluminum moment.” Some history of materials science explains what this means and how it changed the world.

In the mid 1800s, aluminum was viewed as a metal with great promise for technological applications, due to its light weight and high strength. But at that time, aluminum was difficult to extract, making it costlier than silver. Then, an electrolysis method was developed for extracting aluminum and its price dropped 96 percent in little over a decade. We might not appreciate the import of these materials-science innovations today, but Wyss explained that the ability to extract aluminum cheaply allowed us to build airplanes and led to the modern world of global transportation. “Aluminum,” Wyss said, “became a symbol of modernity.”

Now for the Good News

Graphene’s aluminum moment may have already come — and it came at the hands of Professor James Tour. Called “flash graphene,” Tour’s method takes carbon-based material, heats it rapidly using an electric current, and produces high quality graphene at a very low cost. Forbes described this research with the following headline: “Ground-Breaking Method To Make Graphene From Garbage Is Modern-Day Alchemy.”

There are other benefits. Flash graphene works well with plastics, but plastics are only 80-90 percent carbon. Plastics also contain 5-14 percent hydrogen, plus oxygen. Wyss explained that during the flash graphene process, his research has found that a useful byproduct is clean hydrogen, which has many applications, including serving as a source of fuel.

While flash graphene holds great promise Bradley Larschan explained that because it uses the “bottom up” method, it doesn’t produce large flakes of graphene that have special applications. Through a process of electrochemical exfoliation, Larschan noted that large pieces of high-quality graphene can be extracted from graphite. These large pieces have many important applications, including aviation (where aircraft weight might be reduced by a third), electric vehicles (again, allowing lighter-weight materials), and defense (producing ballistic-proof materials). He further noted that graphene can be used as a supercapacitor, which could allow electric vehicle batteries to be more rapidly charged.

Competition Isn’t a Problem

Entrepreneur Ariel Malik noted that carbon nanomolecules also hold great medical promise, as they have been used to rapidly repair severed spinal cords in mice. In light of these promises, Larschan made the comparison between graphene and “plastics” in The Graduate, showing that graphene could revolutionize many forms of technology.

So with Wyss promoting bottom-up-produced flash graphene, and Larschan touting the benefits of top-down-extracted graphene, which method is superior? The panel seemed to agree that they aren’t in competition because they are reaching different market niches and have different beneficial applications. Besides, as George Gilder put it, graphene competition isn’t a problem because “it’s the biggest market opportunity in the world.”